|

|

|

|

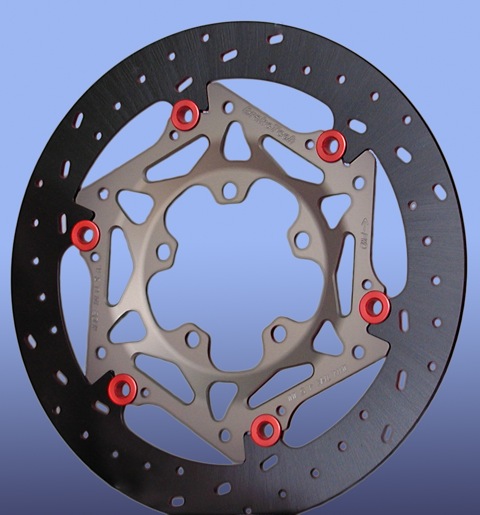

BrakeTech - AXIS/Iron 330mm x 6mm race-spec, Left Side

Updated 09/2012 The exclusive BrakeTech AXIS� series Ductile Iron full-floaters provides a higher coefficient of friction over stainless, with more fe el

and feedback at the brake lever. The patented AXIS Design floating

system is many times stronger than conventional semi-floating brake

rotors. The heart of this leading edge system has the floater buttons

controlling radial and axial float only, they are non load-bearing. All

of the considerable braking forces are channeled through the

trademarked Direct-Link�

architecture, comprising over an 800% increase in surface area load

transfer as compared to conventional floating brake rotors...simply far

superior by design! el

and feedback at the brake lever. The patented AXIS Design floating

system is many times stronger than conventional semi-floating brake

rotors. The heart of this leading edge system has the floater buttons

controlling radial and axial float only, they are non load-bearing. All

of the considerable braking forces are channeled through the

trademarked Direct-Link�

architecture, comprising over an 800% increase in surface area load

transfer as compared to conventional floating brake rotors...simply far

superior by design! PRODUCT FEATURES: - Patented AXIS Design - featuring Direct-Link� load transfer system

- U.S. Patent No. 6,957,726

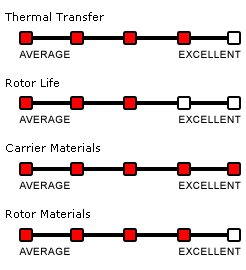

- 50% greater Tensile Strength and Fatigue Strength: Ductile Iron vs Gray Iron

- CNC machined from billet (continuous cast bar) - not porosity prone gravity cast molds

- CRYOGENIC treatment for improved wear resistance

- Greater thermal transfer capability than stainless steel

- Reduced wear from shear forces - longer rotor life

- Carriers CNC machined from premium grade billet aluminum bar - not stamped plate

- Hard-anodized to military grade specifications

- Made in the U.S.A.

Sintered Metal Brake Pads on Iron?There

does indeed exist a universal prohibition against the use of sintered

metal pads on generic cast iron rotors, we have the same warning. But

this caveat is more specifically targeted to old-school gray cast iron

and particularly of the individual molding, gravity feed casting type.

That combination was and is inherently problematic with a propensity

towards suffering from thermal stress induced fracturing. Not good.

The AXIS/Iron on

the other hand is a significantly different animal. Firstly, it is CNC

machined from American made high grade nodular ductile iron, not gray

iron. Secondly, it's a genuine billet part, sawed from continuous cast

bar (which eliminates porosity and the problems associated with that).

Thirdly, it is an inherently stronger material with tensile strength

more akin to steel than gray iron. Plus, besides traditional

heat-treat, we also Cryogenically process them to improve their abrasion

resistance and reduce wear. But bear in mind, they are still "softer"

than stainless steel, which simply stated means you cannot run any pad

you want without the potential for problems developing...

We test

extensively with virtually all the Ferodo sintered metal pads to assure

compatibility with our ductile iron rotors, which is why we can

recommend the Ferodo SinterGrip ST, XRAC and ZRAC pads for this

application. Though along with virtually all other sintered metal

formulations, they will likely result in a somewhat shortened rotor life

compared to the organic alternative. For those with a nagging concern

regarding the wear issue, we recommend the new Carbon/ceramic CP1race

pads. They are a brilliant performer on stainless, and even better on

iron and as such, are more than worthy of your consideration for race

use on all iron rotors. AXIS/Iron Black GunKote:

This is a rust inhibiting coating which is thermally bonded on to

minimize corrosion. It must be cleared from the pad sweep area before

the rotors become fully functional. Please click here for the one page

instruction guide: AXIS/Iron Rotor Clearing instructions

|

|

|

|

|

|

|

|

|